- EN

- ABOUT US

- PRODUCTS & SOLUTIONS

- Mobile System

- In-Channel Screw Screens

- In-Piping Screw Screens

- High-Capacity Screens

- Membrane Protection

- Pump Protection Screens

- Comby Plants

- Septage Receiving Stations

- Mechanical Screenings Treatment

- Grit Handling

- Conveyors

- Mixing & Blending

- Floatation

- Micro-Filtration

- Sludge Treatment Solutions

- Components

- Special Applications

- INDUSTRIES

- Municipal Primary Treatment

- Municipal Secondary Treatment

- Municipal Tertiary Treatment

- Municipal Sludge Treatment

- Poultry Industry

- Canning Industry

- Wine Industry

- Slaughterhouse Industry

- Pulp & Paper Industry

- Tanning Industry

- Hazardous-Waste Industry

- Municipals Solid-Waste Industry

- Dairy Industry

- Precast Industry

- Concrete Industry

- QUALITY & INNOVATION

- CONTACT US

- FIND US

- NEWS & INSIGHTS

OUR HISTORY

metalcarp: the origin of passion

Starting from the years of Metalcarp, which has been for 50 years a well-recognized

custom fabrication shop in Reggio Emilia (Italy), where the technique and knowledge

in the art of fabrication has proven in many fields, R.E.M. founder Matteo Lirici

learned under his father, Alfio Lirici, the dedication to the fabrication and the secrets of steel working.

Metalcarp has shown the creativity and ability of fabrication typical of the Emilia area in many field:

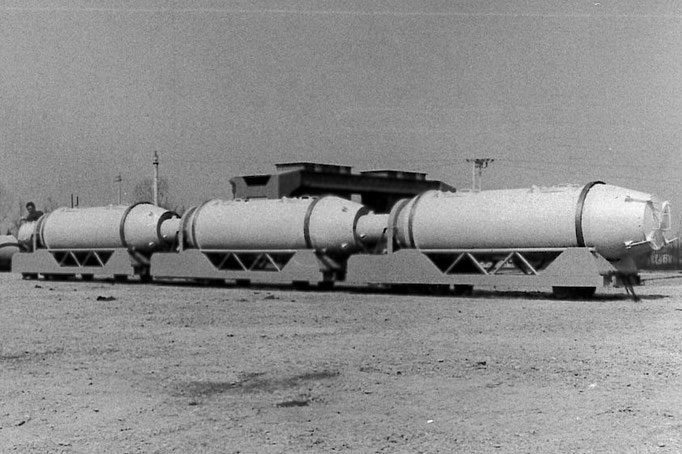

from the very first screens for the river water pumping stations made in the ‘60s,

to the first concrete Mixing Truck ever built in Italy, the Locomotives for ABB, Greco and Matisa,

the early design of Screw Press in the ‘70s up to the Monument Evoluzione

made to celebrate Ferrari and the mechanical and automotive industry in the area.

It is now a landmark which you may see as soon as you arrive in Reggio Emilia.

The experience and ability was transferred to R.E.M. and Alfio has been a great asset

to set-up the fabrication.

R.E.M.: PAST, PRESENT & FUTURE

The long history of engineering and manufacturing ability from the founder, Matteo Lirici,

has joined the creative mind of Milena Marazzi.

From 2003 Matteo and Milena are running the company with a great team of well-trained people.

Having always pursued a quality product policy the main focus of the company

has always been a continuous improvement.

Whereas other manufacturers are focusing on low-end products with a design

that goes back to the 80’s, R.E.M. clearly focused on high quality and new design developments.

The proprietary design of the complete range of units was a huge effort for the company.

Nevertheless R.E.M. can now offer the whole package for the WWTP from primary to sludge dewatering.

Still the desire to innovate and integrate was leading the company to enter into the solids

and solid waste handling. The various installations of silos, powder dosage and mixing, conveyors

and specialized piece of equipment were a step into the offer of complete systems for bulk solids handling as well as special projects in the Hazardous waste handling including hospital waste

and calcium carbonate and pozzolan storage and dosage in Waste-to-Energy plants.

The special abilities of R.E.M. have been recognized from the early years

with world leading projects such as:

- Parts for the Conveyors of Changi WWTP in Singapore.

- Complete Plants in Trbovlje and Zagorje in Slovenia.

- Biogas production Plant of Unipeg (now part of Cremonini) with the whole Wastewater and Solid Waste Handling Plants.

- Ultra Fine Screening at Samsung and LG Plants in Korea.

The innovation has marked the whole history of R.E.M. and the patents for the dewatering and condition of sludge as well as the high performance screen for mesh screenings.

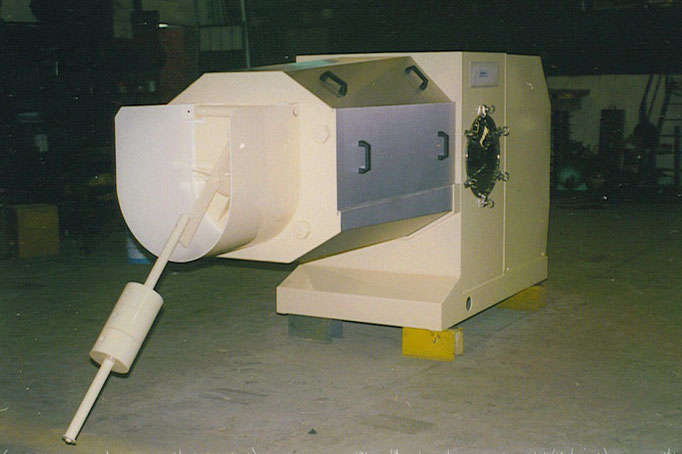

The years have been marked by very special projects such as the automated refrigerated storage facility for the hospital waste with full tracking of waste containers and the laboratory testing equipment for IP9x and Thermal shock testing.

ABOUT US

R.E.M. is a well-known

international company

specialized in equipment design

and manufacturing for the treatment

of primary, secondary and tertiary treatments of wastewater,

sludges and drinking water.

CONTACT US

R.E.M. srl Unipersonale

Via dell'Industria, 53/C | Zona Industriale Corte Tegge 42025 | Cavriago (RE) | ITALY

info@remintl.com

Tel +39 0522 1530338

CONTACT US

R.E.M. Automation Inc.

224 Buffalo Avenue | Freeport | New York 11520 | UNITED STATES

rema@remintl.com

Tel +1 732 993 9093